Your shopping cart is currently empty.

Vibratory Feeders

CF-A Air Powered Vibratory Feeder

Our CF-A Series of air powered feeders are economical and effective, while meeting demands for feed rates up to 50 tons per hour in hazardous and explosion proof environments.

EMF Electromechanical Vibratory Feeder

EMF models all produce a linear motion that provides smooth, uniform, volumetric flow which is fully adjustable. Units are mounted horizontally, requiring no gravitational assistance for product co...

RFM Volumetric Vibratory Feeder

Our Volumetric Feeder Machines are self-contained units incorporating a bulk supply hopper with a vibrator and vibratory feeder.

CT-A Air Powered Vibratory Tube Feeder

Feed and convey dusty material loads or other powder bulk materials that require protection from environmental elements in hazardous areas with economical Air Powered Tube Feeders.

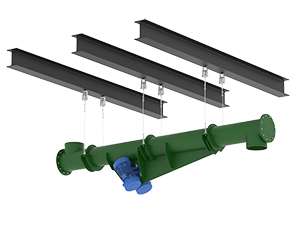

EMF-T Vibratory Tube Feeder

Electromechanical Vibratory Tube Feeders feature a totally enclosed tube tray that is optimal for conveying dusty material loads or other fragile loads that require sanitary surfaces and protection...

The Cleveland Vibrator Company's vibratory feeder machines are used to feed raw materials or finished products into mixers, furnaces, production processes or final containers. Available in a wide variety of styles and finishes, Cleveland Vibrator's linear vibrating feeders are ideal for foundries or the chemical, food, metal or paper industries. Fully adjustable volumetric flow allow for automated or semi-automated production processes or fill stations.

Our team provides decades of design and consultative experience that will ensure the best, custom built vibratory pan feeder solution for your unique application. Learn more today!

Benefits of vibratory feeding include:

- Lower production cost and improved quality and throughput by ensuring controlled and consistent material flow

- Reduced cost of maintenance and part replacement compared to mechanical feeders

- Flexibility in design options ensures a seamless fit into your existing production processes for your specific application

- Safety under the most hazardous conditions

- Controlled flow of ingredients to mixing tanks

- Sprinkling toppings or coatings on food and dairy products

- Adding binders and carbons to foundry sand reprocessing systems

- Chemical additive feeding in the pulp and paper bleaching or chip handling processes

- Feeding metal parts to heat treating furnaces

- Feeding scrap or glass cullet to furnaces

SIMPLE PRINCIPLE, GREAT SUCCESS

Hops, Not Streams. While it appears to move in a uniform flowing stream, in reality the material makes a series of short, continuous, rapid hops forward that are imperceptible to the human eye. How does this happen? The power source is attached to the feeder at a prescribed angle. The force and angle create a forward and upward motion of materials but returns back to its original position. However, the material doesn't move backwards due to the slower action of gravity happening during the return motion.

DESIGNED FOR YOU, YOUR MATERIAL AND YOUR PROCESS

Design Experience. The Cleveland Vibrator Team has over 60 years of collective experience sizing and designing vibratory feeders and conveyors for 100's of different materials and applications. So, you can be rest assured we will get the force, frequency, amplitude and custom options right that will make your project successful.

Design Experience. The Cleveland Vibrator Team has over 60 years of collective experience sizing and designing vibratory feeders and conveyors for 100's of different materials and applications. So, you can be rest assured we will get the force, frequency, amplitude and custom options right that will make your project successful.Simple. Our Vibratory Feeders and Conveyors are designed and built for minimal wear parts to make maintenance an infrequent and easy task.

Large Bulk Material Loads? No Problem. Cleveland Vibrator has experience designing and building vibratory feeders and conveyors durable enough to vibrate loads at a rate of up to 300 tons per hour.

In-House Product Testing. Cleveland Vibrator's in house testing lab includes an EMF Electromechanical Vibratory Feeder with independent variable frequency and variable amplitude controls to allow determination of optimal vibration conditions for any material AND prediction of feed rates and process outcomes. Videoing of in-house testing is made available to the customer through a private channel.

Quality Components. Uras Techno Rotary Electric Motors, Yaskawa Controls, Firestone Isolation Mounts, Mettler-Toledo Weigh Modules, to name a few. We use only the best brands of components on our vibratory equipment, recognized for quality and continuous duty.

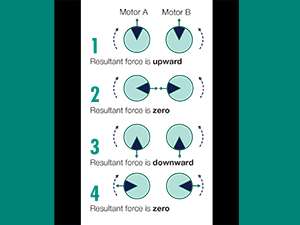

Linear Vibration. Sure, using one motor would cost less. But, 99% of vibratory equipment applications perform best with linear vibration, in line with gravitational forces, that are easily achieved with two synchronized vibrator motors, using the Dual Motor Principle.

TAILORED ON DEMAND

- Tray Shapes - Vibratory Feeder capacity will vary with tray configurations. A tubular or vee-shaped tray will not move the same volume as a standard flat tray.

- Discharge Options - Vibratory Feeder Discharge Options include: Standard flute chute, tapered chute, circular chute or side discharge

- Equipment Options - Levelling gate, dust cover, liners and impact plates are available to add to your uniquely designed vibratory feeder conveyor to provide the best material flow solution for your specific bulk material

- Isolation Options - Air mounts, coil springs, sandwich rubber and Marsh-Mellow Mounts

- Control Options - Electromechanical (Magnetic starter, variable frequency, dynamic brake), Air Powered (Filter regulator lubricator FRL, explosion-proof solenoid), Electromagnetic (Variable amplitude) and Special Controls including remote operation, two-speed, batch weighing and multiple feeders.

- Drive Locations - The most widely used or preferred method is Cleveland Vibrator's standard below-deck mounting of air or electric vibrators. When there are particular installation requires that dictate vibrator mounting location, above-deck mounting can be used. Side-mount option is available with the use of Rotary Electric Vibrators on the vibratory feeder conveyor.

- Trough Coatings - Our vibratory feeder conveyors are available in a variety of trough shapes. Units can be furnished with special trough coatings such as neoprene, UHMW, urethane, non-stick polymer, non-stick textured surfaces or removable abrasive-resistant steel plate. The trough can be furnished in steel or polished stainless steel to meet the most demanding requirements.