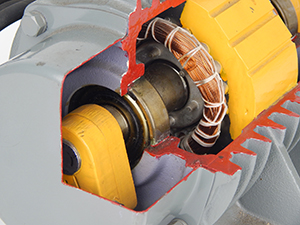

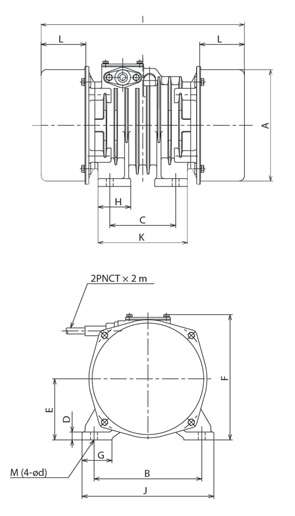

4-Pole Rotary Electric Vibrators RE 9-4S (KEE 9-4S)

The Cleveland Vibrator Co. RE line 3-Phase 4-Pole Rotary ElectricVibrators feature forces ranging from 330 Lbs to 24,200 Lbs at frequencyof 1800 RPM. Rugged construction and environmentally protected designmakes these units ideal for dusty indoor environments or outdooroperation on packing or settling tables, screeners, feeders or as flowaids on bins and hoppers. Model RE 9-4S is a great replacement motor for use on Tyler V-85 Hummer style screeners.

DURABLE - fully enclosed construction (TENV) andcontinuous duty rating provide for a long service life in harshconditions. Most units have permanently greased bearings for reducingmaintenance requirements.

SAFE - units run at average of 58 dbA at four feet

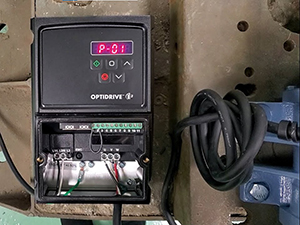

VERSATILE - each unit has adjustable force outputs withmost units being fully adjustable from 0%-100% force output rather thanbeing limited to pre-set stop points.

EASY - all units come with Grade 5 mounting fasteners as well as a pre-installed, anti-vibrational lead cable

All 575V Models are now CSA Approved!

Click the button at left to order the 4-pole electric vibrator that meets your needs, or contact us now to learn how our rotary electric vibrators can make a difference in your operations.

RE 9-4S (KEE 9-4S)

94.00 lbs

1/2

1,980 Lbs. (9 kN)

1.7 (.99)

IP66