Vibratory Equipment

Your application may be so unique that a cookie-cutter piece of equipment just won’t cut it. That’s when you need a custom-made piece of vibratory equipment from Cleveland Vibrator Company.

We’re a team of problem solvers. We work with you to understand your particular needs and then build the right solution to fill them. With decades of vibrational material handling experience, our knowledge base comes from thousands of vibratory feeder, vibratory table and vibratory screener equipment build projects for hundreds of material types. That’s why we recognize your project’s success could hinge on knowing:

- Which vibration frequency is best for a table consolidating 0” slump concrete and which is best for 3” slump concrete

- What force to use on a vibratory compaction table for no-bake foundry sand and what force to use for a vibratory shake-out table

- How long powder plastic resin needs to be in contact with a vibrating screen surface vs. how long powder metal needs to be on a fine mesh vibratory screener or sifter machine

- What vibrational stroke to use on a feeder for small metal parts vs. large metal parts

To name a few...

Whether you need vibration to screen, pack, feed, convey, consolidate or deair; whether your material is bulk metal parts, bulk fruit or nuts, light or heavy powders, foundry sands, refractory mix, concrete, aggregate or mined materials, we have what it takes to make your project a success. And we have the know-how to build equipment that will last.

Our equipment can include extensive options, like high-tech coatings, digital weighing instruments and variable frequency controls. We provide full 1:1 consulting and design services, product drawings, product manuals, parts lists with reference numbers and a 1-year warranty. Call us or submit a quote request form from any of the equipment types below to start working with us on your project today.

Since 1923, we've worked with 15,000 organizations worldwide to find solutions to keep their production moving. Check out our YouTube Channel where you can find hundreds of videos of our products in action.

Vibratory Feeders

Cleveland Vibrator offers a wide range of vibratory pan feeders that provide smooth, uniform & adjustable volumetric flow of bulk materials with significant cost advantages over mechanical feed...

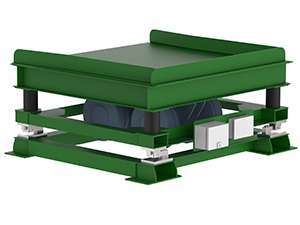

Vibratory Tables

The Cleveland Vibrator Company offers a wide range of light, medium, and heavy-duty vibratory tables and vibratory packers for settling and compacting bulk materials.

Vibratory Screeners

Multiple screener, scalper & sieves design options are available to size and separate materials, or remove unwanted materials from a batch, such as liquids, fines or over-sized product.

Fine Mesh Vibratory Sieves, Sifters and Screeners

HK Technologies fine mesh screening equipment significantly improve rates for screening, sifting, sieving and sizing of materials from 5 micron to #10 mesh in lab or production environments.

Vibratory Packers and Joggers

The Cleveland Vibrator Company offers a wide range vibratory joggers and packers for settling and compacting light to medium bulk material load applications.