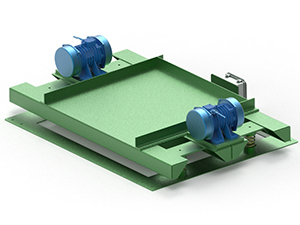

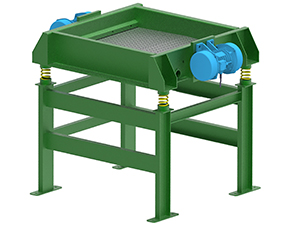

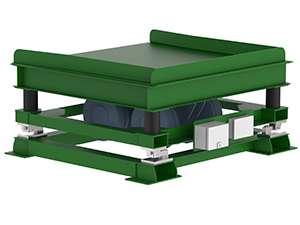

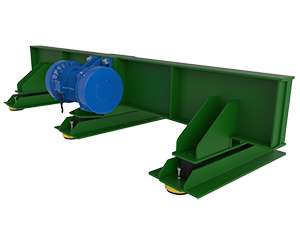

Vibratory Tables

Vibration tables from Cleveland Vibrator handle tough material challenges of condensing, settling, densifying, de-airing and packing. Designed to improve your current operations, our multiple models provide options to fit your needs in production, filling and packing or weighing. The use of low-maintenance, continuous duty rated vibrators ensure long and low-cost equipment life span. The flexibility in design options ensures that you get the right solution for your specific material and application. A wide range of light, medium and heavy-duty vibratory compaction tables and packers are available. We offer FREE material compaction testing prior to purchasing! Contact our team for more information.

Benefits of our vibration tables include:

- Cut container costs by as much as 20% by fitting more material in every box, drum, bulk bag or Gaylord

- Decrease material loss in transit by compacting and stabilizing materials prior to shipment

- Decrease shipping costs by fitting more material per shipment

- Improve structural and surface quality of precast products by quick consolidation of material to eliminate voids and air bubbles

- Reduce labor and time in processing and packaging.

- Consolidation of concrete and other castable refractories

- Foundry shake-out

- Product quality and fatigue testing

- Compact bulk material loads into containers

- Removes voids and air pockets in molds

- Flatten bulk bags prior to palletizing

- Fully automated fill stations

- Accurate container weights

- Containers filled, weighed and closed in less time than with manual installations

- Maximum compaction typically is reached within 10-30 seconds depending on material load

Cut Down on Container Costs. Typically, bulk material will compact down by 20% of its aerated state. Materials that normally fill five bulk material containers can be reduced to only four, saving on container and storage costs by using vibratory tables.

Cut Down on Container Costs. Typically, bulk material will compact down by 20% of its aerated state. Materials that normally fill five bulk material containers can be reduced to only four, saving on container and storage costs by using vibratory tables. Select a vibratory table below or contact us now for more information on our full line of industrial vibratory equipment.