Your shopping cart is currently empty.

Plastics

Cleveland Vibrator Company offers a full range of industrial vibrators and equipment for manufacturing plastic pellets and small plastic parts.

Benefits of Industrial Feeders & Screeners during Plastic Regrind Processes

Include:

- Customizable Vibratory Feeders give you an option to allow a steady flow of plastic scraps into your hopper leading into your grinding system

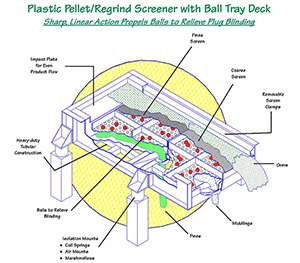

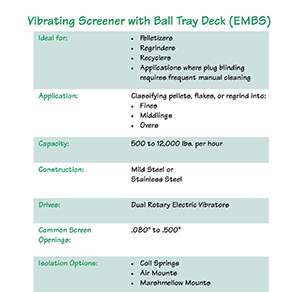

- Using Vibratory Screeners to help distinguish proper sizing of appropriate regrind from non-usable plastic materials

- Double Deck Systems and Ball Decks are available for this Screening Application - This addition to you Vibratory Screener provides better efficiency in your process and will reduce excess waste

- Using Vibratory Screening will help to eliminate the amount of dust particles and incorrectly sized pellets

- By removing excess dust and incorrectly sized regrind, it allows mixing regrind with virgin resin to result with an end product with little-to-no blemishes or discolorations

- Multiple screen deck mesh sizes are available

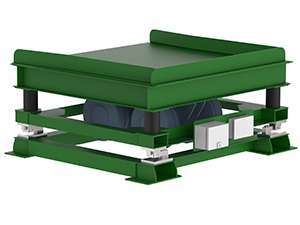

- Vibratory Tables provide an efficient way to settle and pack your end-product to eliminate wasting excess storage space within your gaylord or container

- FA Flat Deck Model or Vibratory Packer Model aids in settling molded/cast products

Benefits of Industrial Vibratory Tables during

Plastic Regrind Processes Include:

- Cut container costs by as much as 20% by fitting more material in every bulk bag or Gaylord container

- Decrease material loss in transit by compacting and stabilizing materials prior to shipment

- Decrease shipping costs by fitting more material per shipment

Benefits of our Vibratory Units for the Plastics Industry include:

- We offer a wide range of different Vibratory Units for bins, hopper and chutes of plastic pellets or pigments/additives

- Vibrators for small parts tracks

Click on the links below or contact us now for more information on our full line of industrial vibrators and vibratory equipment.