Your shopping cart is currently empty.

2-Pole Rotary Electric Vibrators RE 2-2 (KEE 2-2)

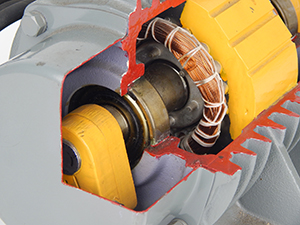

The Cleveland Vibrator Co. (RE) & Uras Techno® (KEE) line 3-Phase 2-Pole Rotary Electric Vibrators feature forces ranging from 110 Lbs to 8,800 Lbs at frequency of 3600 RPM. Rugged construction and environmentally protected design makes these units ideal for dusty indoor environments or outdoor operation on packing or settling tables, screeners, feeders or as flow aids on bins and hoppers.

Our 2-Pole Rotary Electric Vibrators are ideal for dusty environments or outdoor operation on packing or settling tables, screeners or feeders, thanks to features like their:

- Rugged construction

- Environmentally protected design

Also suitable as flow aids on bins and hoppers, these electrical vibrators are known and trusted to be:

DURABLE - fully enclosed construction (TENV) and continuous duty rating provide for a long service life in harsh conditions. Most units have permanently greased bearings for reducing maintenance requirements.

SAFE - units run at average of 58 dbA at four feet

VERSATILE - each unit has adjustable force outputs with most units being fully adjustable from 0%-100% force output rather than being limited to pre-set stop points.

EASY - all units come with Grade 5 mounting fasteners as well as a pre-installed, anti-vibrational lead cable

SAFE - units run at average of 58 dbA at four feet

VERSATILE - each unit has adjustable force outputs with most units being fully adjustable from 0%-100% force output rather than being limited to pre-set stop points.

EASY - all units come with Grade 5 mounting fasteners as well as a pre-installed, anti-vibrational lead cable

Click the button at left to order the 2-pole electric vibrator that meets your needs, or contact us now to learn how our rotary electric vibrators can make a difference in your operations.

Questions on the RE, RES or KEE, SEE model names? A Cleveland Vibrator Model RE 80-6 is the same as a URAS KEE 80-6 and the Single Phase RES 1-2 is the equivalent to a Uras Model SEE 1-2.

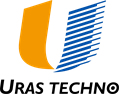

RE 2-2 (KEE 2-2)

A

4-11/32" (11.0cm)

B

4-23/32" (12.0cm)

C

1-37/64" (4.0cm)

D

3/8" (1.0cm)

E

2-7/32" (6.3cm)

F

5-15/16" (15.0cm)

G

1-19/64" (3.3cm)

H

NA

I

9-1/16" (23.0cm)

J

5-23/32" (14.5cm)

K

2-9/16" (7.0cm)

L

1-31/32" (5.0cm)

M

13/32" (1.0cm)

Weight

18.70 lbs

H.P.

1/5

Max Force

440 lbs (2kN)

Amp Draw @ Volts 230 (460)

0.65 (0.39)

Protection Structure

IP66

![[INFOGRAPHIC] How to Adjust the Eccentric Weights of Rotary Electric Vibrators](/images/Documents/How to Adjust the Eccentric Weights of Rotary Electric Vibrators -web.jpg)